As a design engineer for power electronics systems you require your selected power module to fulfill its electrical function as described in its data sheet and you expect this module to be reliable meaning that it should operate under given conditions in a defined period of time and.

Ceramic substrate health hazzards.

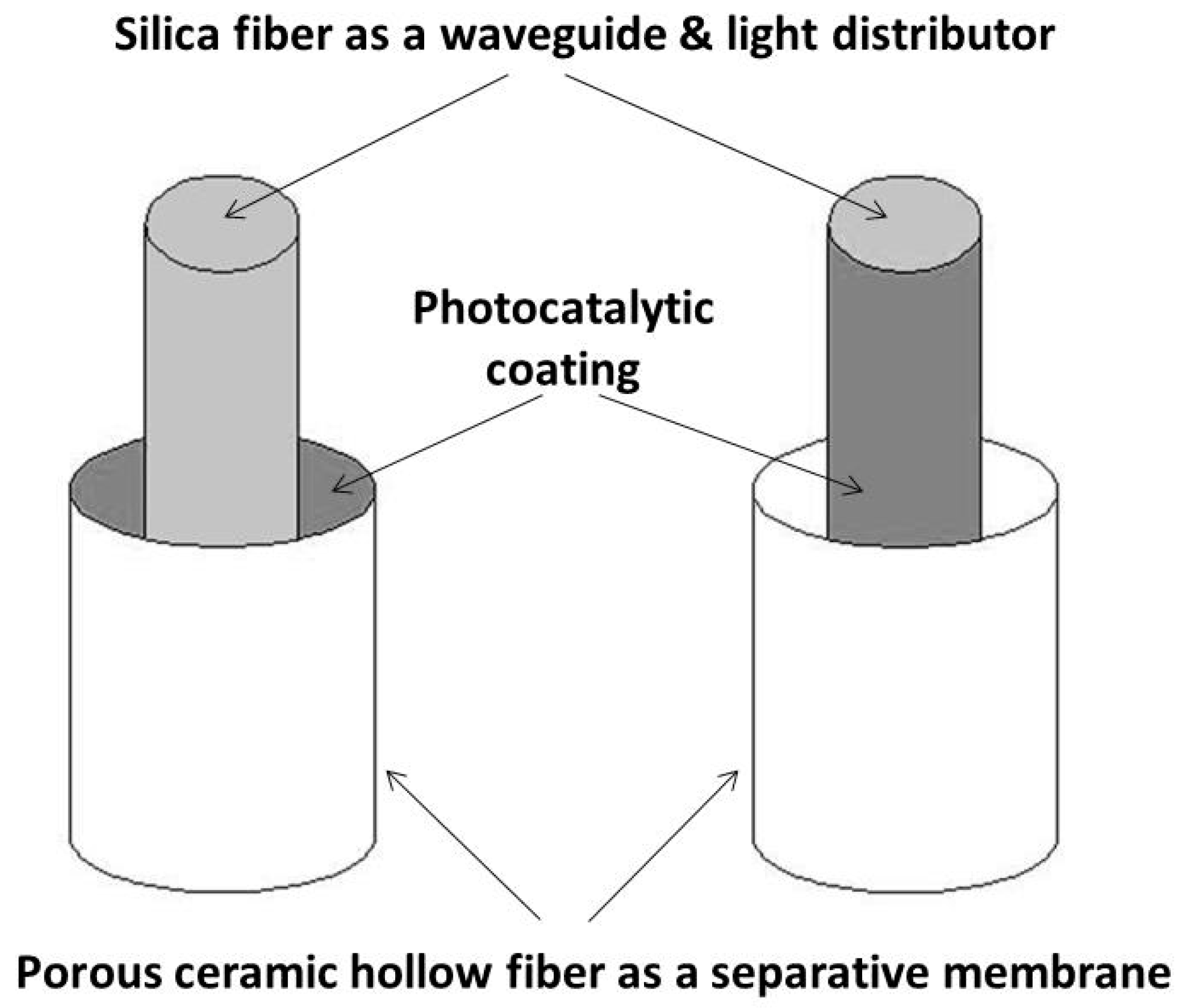

The substrate onto which the active catalyst is deposited is an area in which great progress has been made.

Ceramic fiber textile cloth tape twisted rope round braid square braid sleeving yarn chemical name.

If you ve been wondering about ceramic cookware health hazards there are some important facts to know.

Potential leaching of finished ware clay.

Our curamik power plus substrates are based on zr doped al 2 o 3 hps ceramic.

These substrates offer a longer lifetime and greater reliability and performance than alumina substrates and it comes at a competitive price point.

Health effects are both similar and more irritating compared with most other kiln gases.

The specific hazards and precautions can be divided into the following areas.

The doping process provides enhanced robustness and improved properties when exposed to mechanical constraints.

Often local environmental protection laws ban salt kilns.

Ceramic and cookware cookware is typically anything food is cooked which could mean actual ceramic based dishes in the form of casseroles trays and baking pots lidded or otherwise.

Plaster and plaster molds 3.

On first introduction in 1974 ceramic substrates had a density of 200 cells per square inch of cross section or cpsi 31 cells square cm and a wall thickness of 0 012 inch or 12 mil 0.

Hydrogen chloride gas is highly toxic by inhalation.

Working with clay 2.

Chemical product and company identification product name.

Read the product specific safety data sheet sds for additional environmental health and safety information before working with beo.

Hydrogen chloride and water vapor form hydrochloric acid which can corrode metal fittings in the area.

Overview of ceramic substrates.

Aluminosilicate fiber trade name.

Ceramic substrate is based on the electronic ceramic with the membrane circuit element outside and the fitting element to form a support base for the sheet material the coming out of ceramic substrates opens the new development of the thermal application industry thanks to their characteristics such as high heat dissipation low thermal resistance long life.

Material safety data sheet 1.

In addition processing beryllium oxide shall be conducted in accordance with the beryllium standard for general industry 29 cfr 1910 1024 established by the occupational safety and health administration.

Glazing and coloring 4.

R a searles in studies in surface science and catalysis 1998.

Firing in a kiln 5.

Reliability of metallized ceramic substrates for power electronics applications.

3 3 technology of the substrates.