However siloweigh can use pressure sensors to measure liquid level load cells for high accuracy and weldable gauges for special applications siloweigh ii can also use any 4 20 ma analog sensor allowing you to gain more value by recording temperature or moisture values.

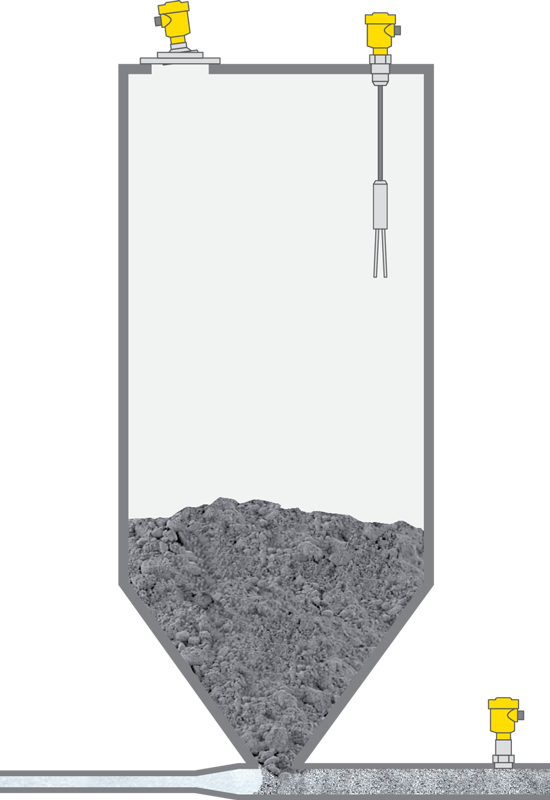

Cement silo level sensor.

The cement is transported both in and out of the silo via pneumatic conveying.

Most silos on legs and skirted silos use the l strain silo weight sensor.

With so many ways to measure level in a silo it can get confusing for consumers shopping for a new level device fortunately we are here to help.

First the cement silo tank liquid level sensor is a sensor used to detect the height change of the material in the container.

It can continuously detect the height volume and other values of the material and transmit the relevant information to the computer or display instrument.

Fesco direct supplies two ingenious silo solutions from scale tron to help keep your business productive and profitable.

The cement is transported both in and out of the silo via pneumatic conveying.

This article deals with the problems of silo level measurement and recommends level measurement devices for various products that are usually stored in silos.

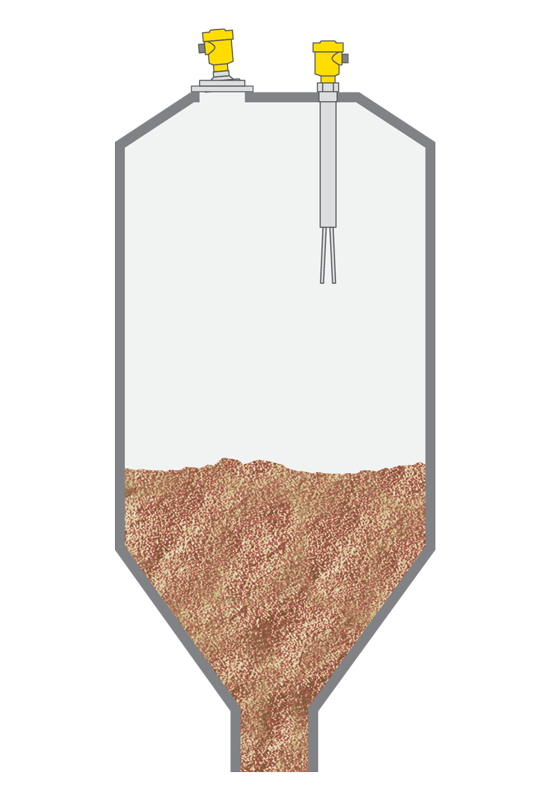

Before further processing the cement is stored in tall silos.

Cement silo raw mill silo additives hopper overflow protection dry run protection.

Binmaster designs and manufactures reliable solid state point and continuous bin level indicators control systems and sensoring devices used while storing powders and bulk solids.

Established in 1953 garner industries is certified to iso 9001 quality management systems requirements.

The silopatrol se continuous level measurement and inventory monitoring system is a truly robust smart cable based weight and cable plumb bob yo yo type bin level sensor system.

Efficient storage and transport of the product is ensured by accurate level measurement and point level detection as well as also monitoring the pneumatic conveying system pressure.

Measuring material level in dusty talc applications for luzenac america.

Concrete batching control systems silo level indicators weighing systems accurate weights are essential for producing quality concrete and to prevent overfilling or running out of material.

The company is a subsidiary of garner industries a custom manufacturer of plastic and metal parts.

To avoid over flow of cement silos and maintain minimum level of the silo need to use precise level sensors for high and low level point level detection.

Before further processing the cement is stored in tall silos.

Cement talc silopatrol level sensor.

It is a field proven approach to reliably monitoring the level of material in bins silos and tanks.

Continuous silo level detection and inventory management of ready mix cement sand aggregates.

Efficient storage and transport of the product is ensured by accurate level measurement and point level detection as well as also monitoring the pneumatic conveying system pressure.